Its a Double: Another Framework win!

Lintott Control Systems Limited is delighted to advise that it is the only supplier to be awarded two (liquid) Chemical Dosing Framework Lots for Thames Water (FA1310 Chemical Dosing Equipment). The Lot 2 agreement covers liquid disinfection, and Lot 4, wastewater dosing, which extends the long period & multiple AMP (capital expenditure) periods where Lintott has supplied Thames Water with its portfolio of high-quality solutions.

Thames Water is the UK’s largest water & wastewater services company. Each day, it supplies 2.6 billion litres of fresh water and treats 4.4 billion litres of wastewater – extending to some 15 million customers.

Steve Tyler, Proposals Manager for treatment products at Lintott, commented, “We are thrilled to have been awarded both dosing framework Lots for Thames Water. We recognise the constantly evolving nature of the Sector and we’re therefore constantly seeking to add value and provide innovative integrated solutions. Through this and aligned business activities, we’re committed to assisting Thames Water in delivering the best level of service for its customers.”

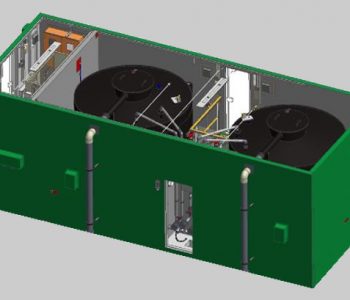

Lintott has one of the most comprehensive ranges of factory-built packaged water & wastewater treatment systems available from one source. This includes solutions for: Temporary dosing; Drinking water treatment (including Fluoridation); Wastewater treatment; Odour control; Sludge treatment; Industrial process water; Water re-use & recycling, & Disinfection. All products are designed to ensure that customers meet their legislative as well as specific business requirements. This is backed by a full package of service & aftercare. Featured above is an example packaged solution. Want to know more? Please email us via media@lintottcs.co.uk.